The First Launch of Cobalt-Free Cathode Materials in the Industry

Through cation doping, single crystal technology, and nano network coating, SVOLT has greatly addressed the major issues that restrict the development of cobalt-free batteries, such as nickel-lithium ion mixing of cobalt-free layered materials and cycle life.

-

90

Domestic technology patents

-

46

International technology patents

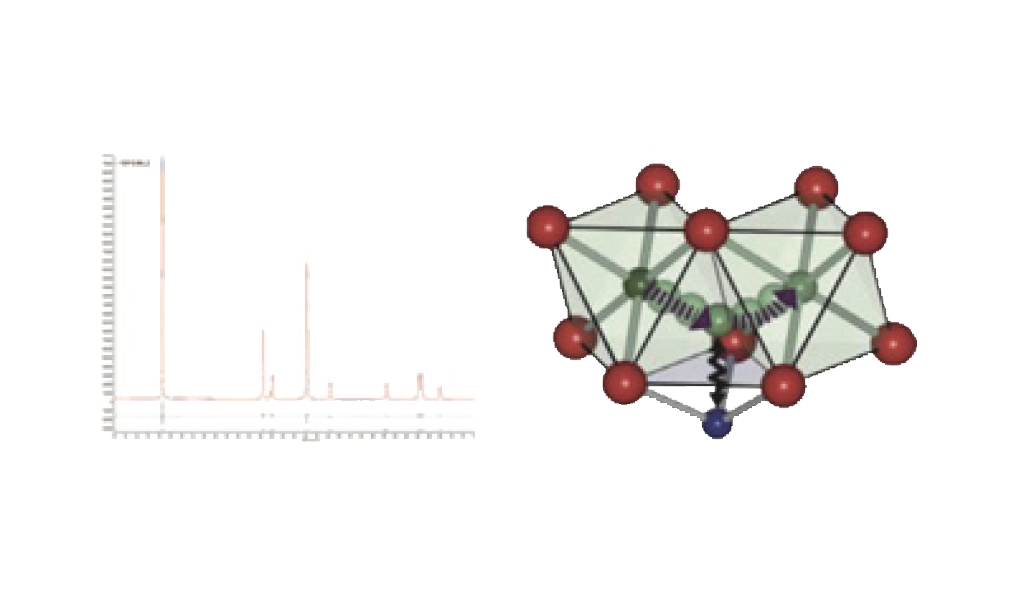

Three Key and Core Technical Supports

-

Cation doping technology

Increase nickel content and reduce mixed discharge of lithium nickel (-5%)

Stable oxygen octahedral structure

-

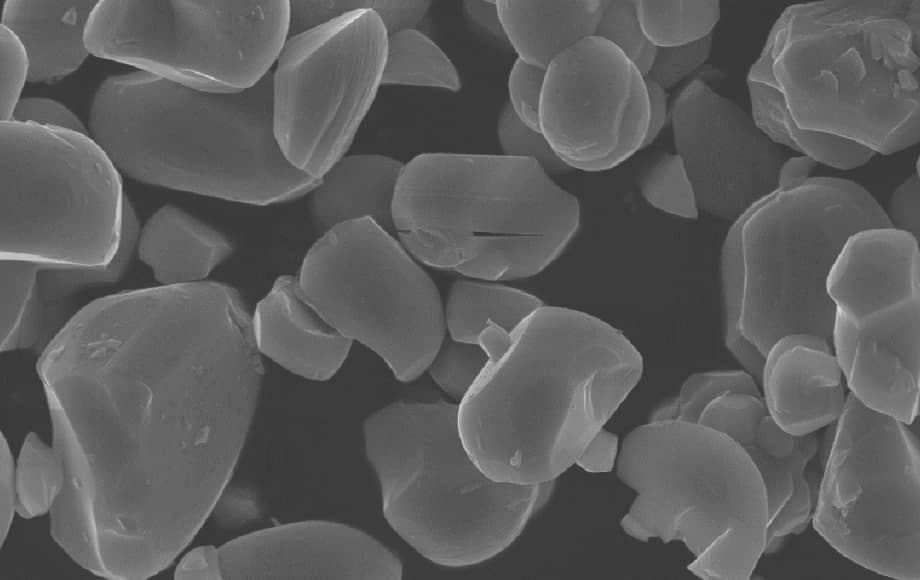

Single crystal technology

-

Nano network coating technology

SVOLT NMX Cobalt-Free Cathode Material

comparative Performance Compared with NCM811 Material

The performance comparison between NMX cobalt-free material and NCM811 NCM material demonstrated that the former is superior to the latter in terms of thermal runaway, thousand cycle life, and BOM cost.

Thermal runaway (°C)

Keep 1000 life cycles

NCM811

155

87

NMx

170

95

New Generation Lithium Iron Materials

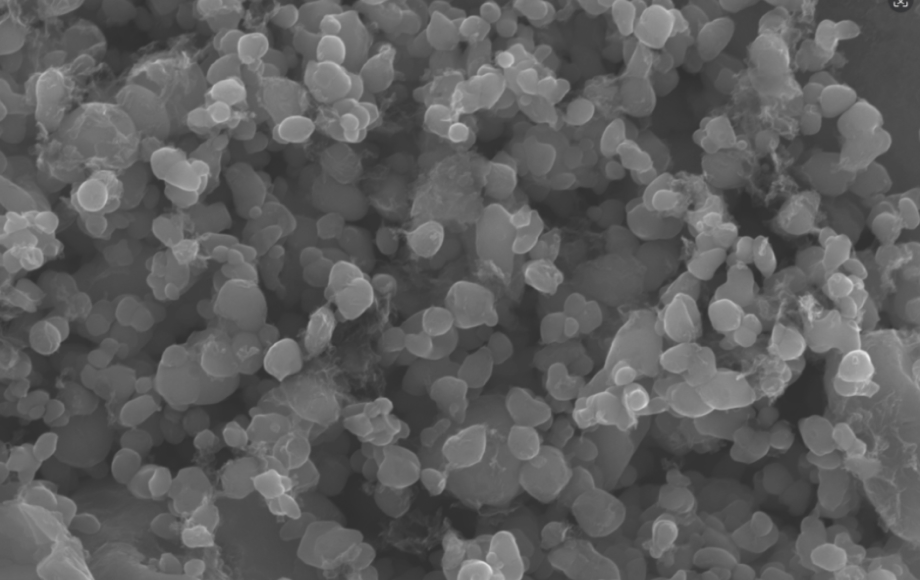

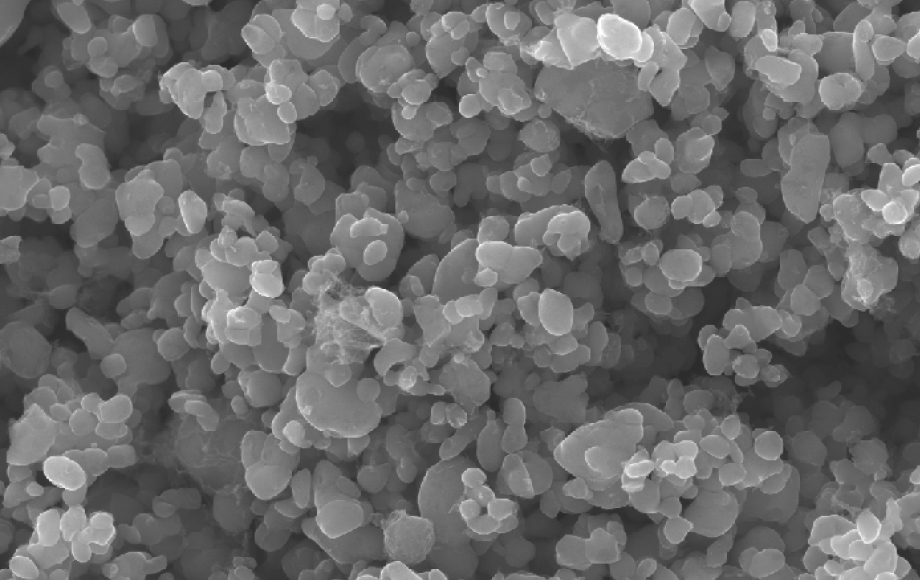

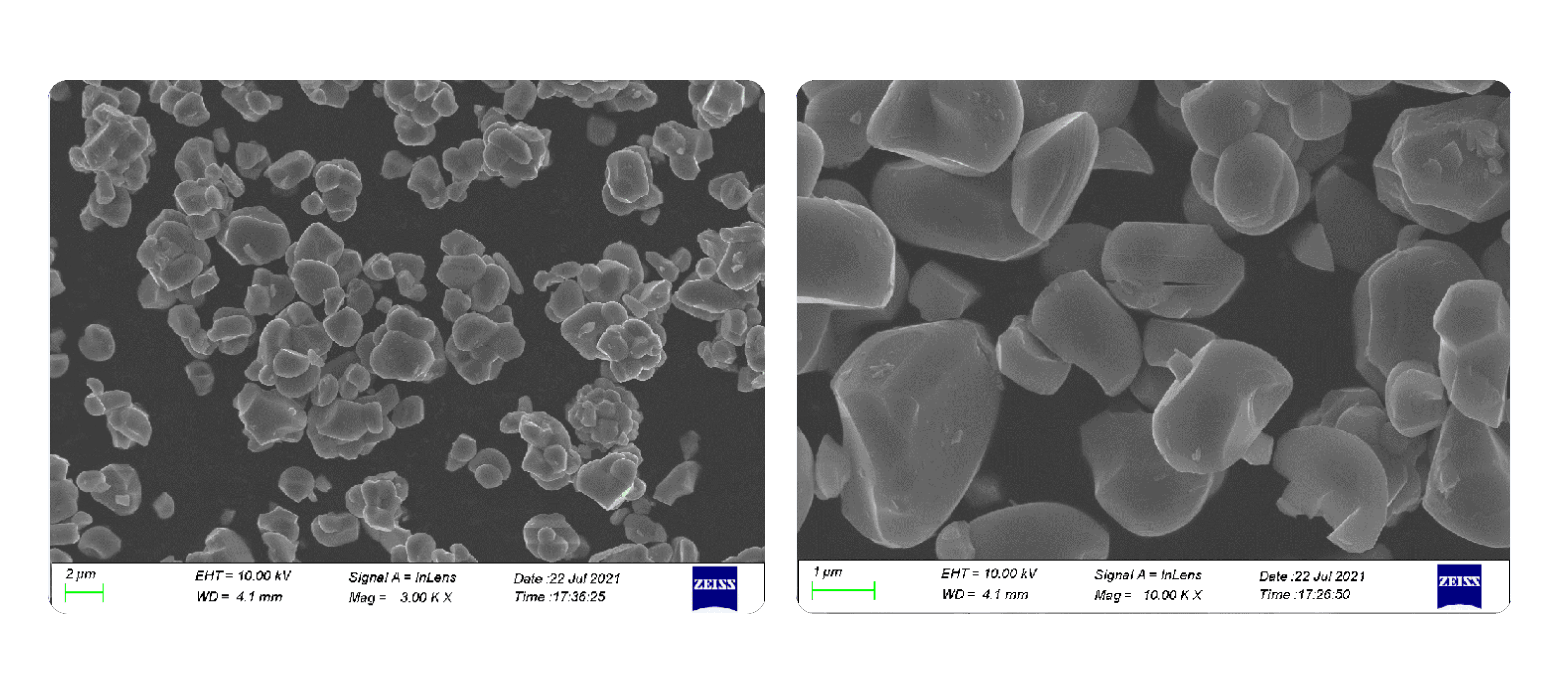

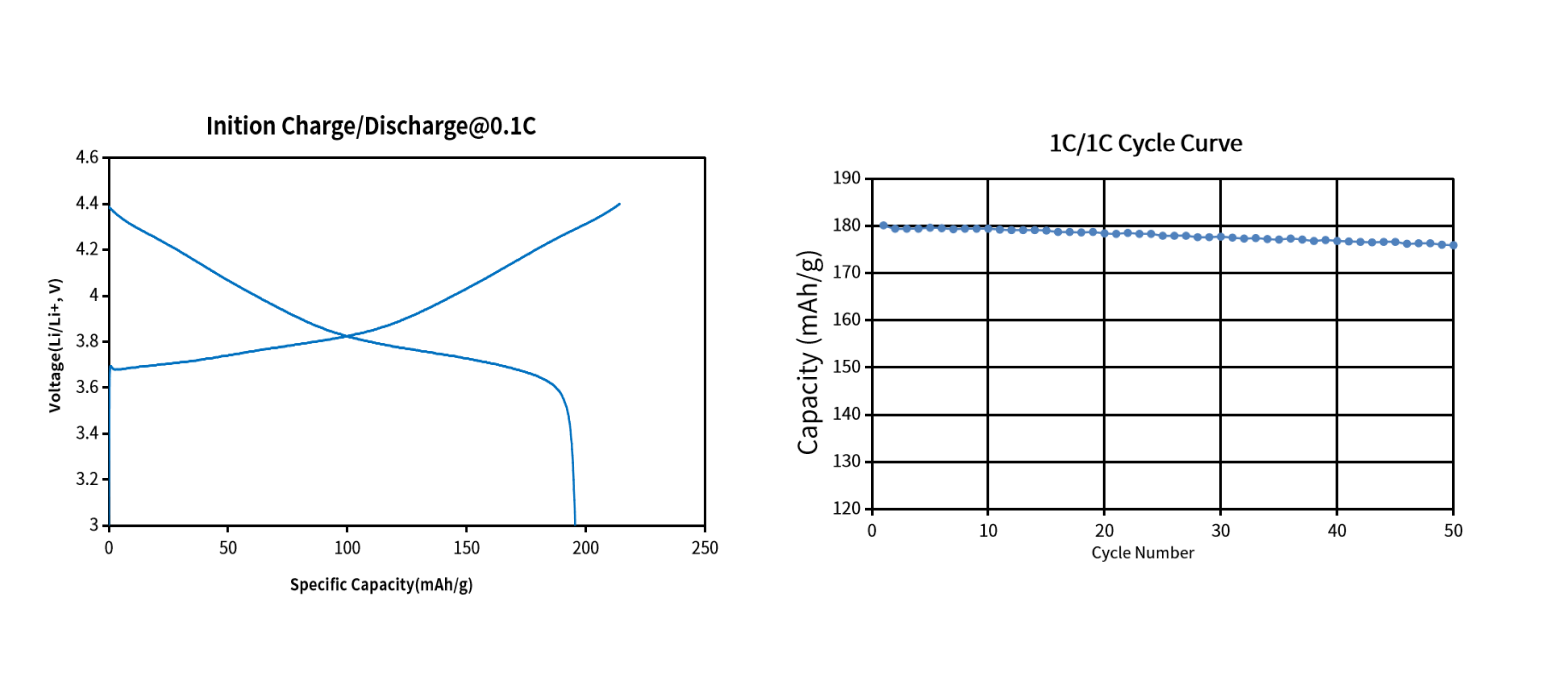

The new generation of high-energy density lithium iron phosphate material is mainly used for power batteries. It has the advantages of higher graphitization and uniformity due to carbon coated layer, better low-temperature performance, as well as higher compaction density characteristic.

Application Fields

-

Electric passenger vehicles

-

Electric logistics vehicles

-

Electric bus

-

Electric two wheeled vehicles

-

Electro-tricycle

-

Energy storage system

Material Characteristics

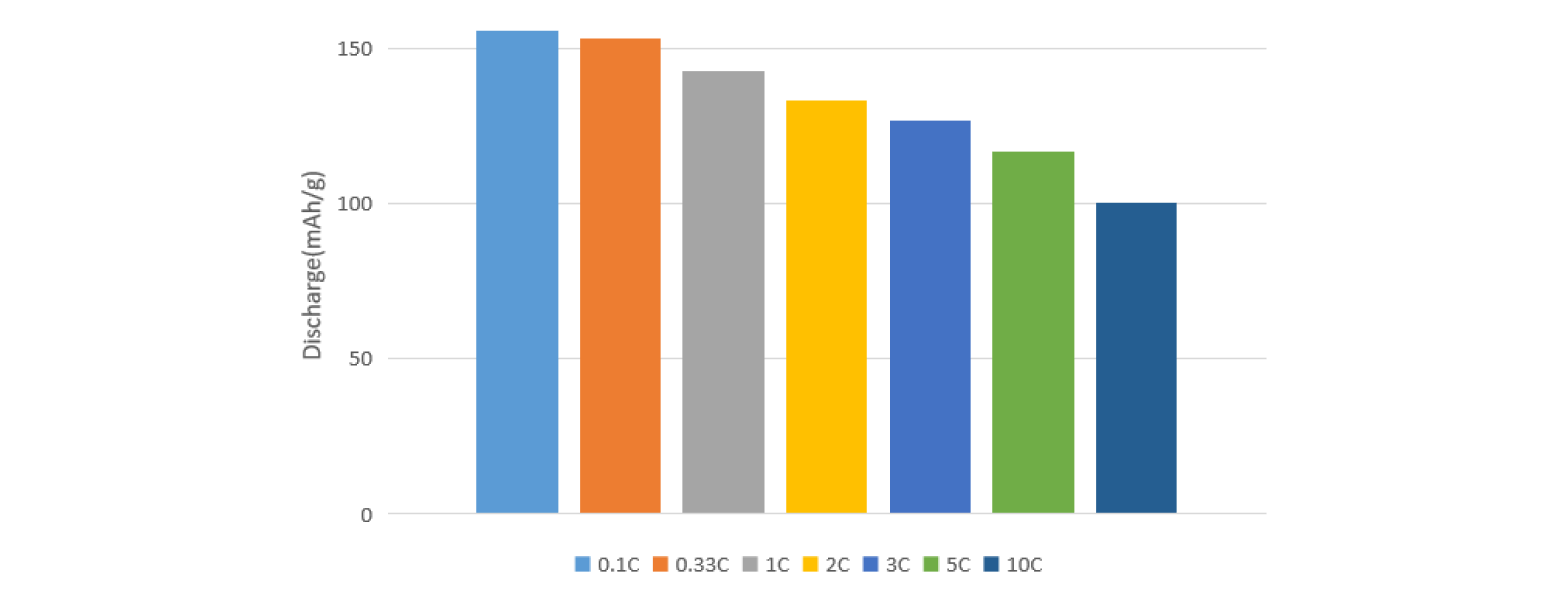

High Performance Advantages

-

More excellent rate performance, with 5C/0.1C capacity retention ratio ≥ 75%.

3,000 cycles, capacity retention ratio ≥ 80%.

Medium-Nickel High-Voltage Ni6 Material

The medium-nickel high-voltage material (Ni6) of SVOLT has a total capacitance of 0.33C ≥ 194mAh/g, which is higher than the competitors (≈ 193mAh/g). The DCR of 50% SOC in normal temperature of 4.4V is 15-20% lower than the competitors, making it suitable for high-energy density fast-charging cell projects.

Application Fields

-

Electric passenger vehicles

-

Electric logistics vehicles

-

Electric two wheeled vehicles

-

Electro-tricycle

Material Characteristics

Core Technological Advantages

-

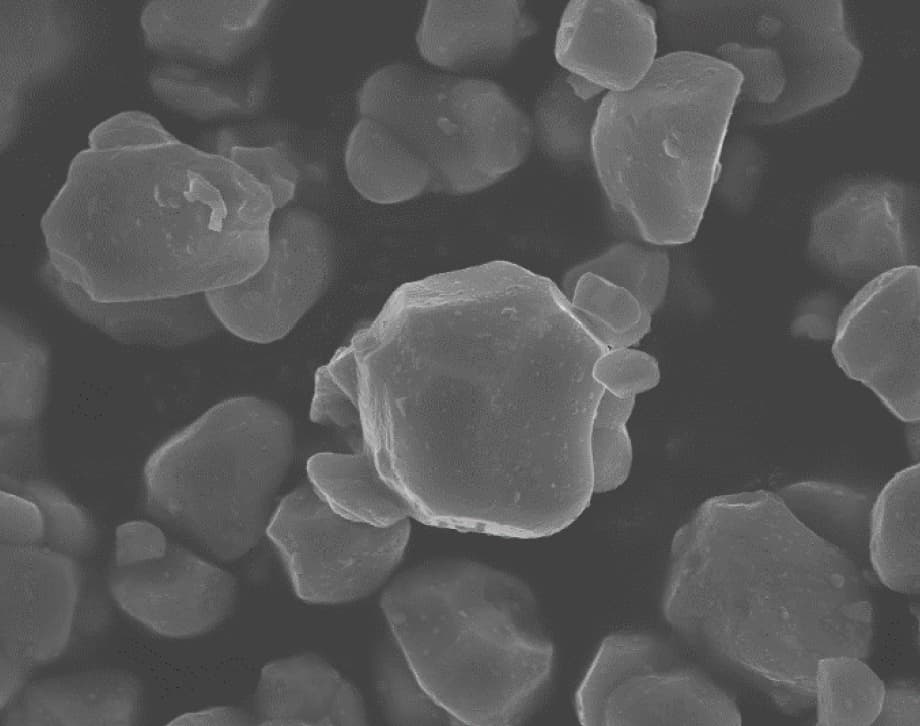

Good dispersion of primary particles, with round edges which is conducive to the capacity utilization.

-

Outstanding electricity deduction (capacity and cycle) performance, with a cycle retention ratio of over 98%.

Medium-Nickel High-Voltage Ternary Material (Ni6)

The performance of medium-nickel high-voltage ternary material (Ni6) is superior is better than high nickel material in different systems.

The 4.35V system is subject to excellent cycling performance and lower gas production for better service life and safety;

The 4.4V system has a higher energy density, which can match(satisfy) more demands and provide more choices in application directions;

No matter under the 4.35V or 4.4V system, the service life and safety of medium-nickel material are better than high nickel material, and the energy density is close to that of high nickel material, which is a cost-effective cathode material.